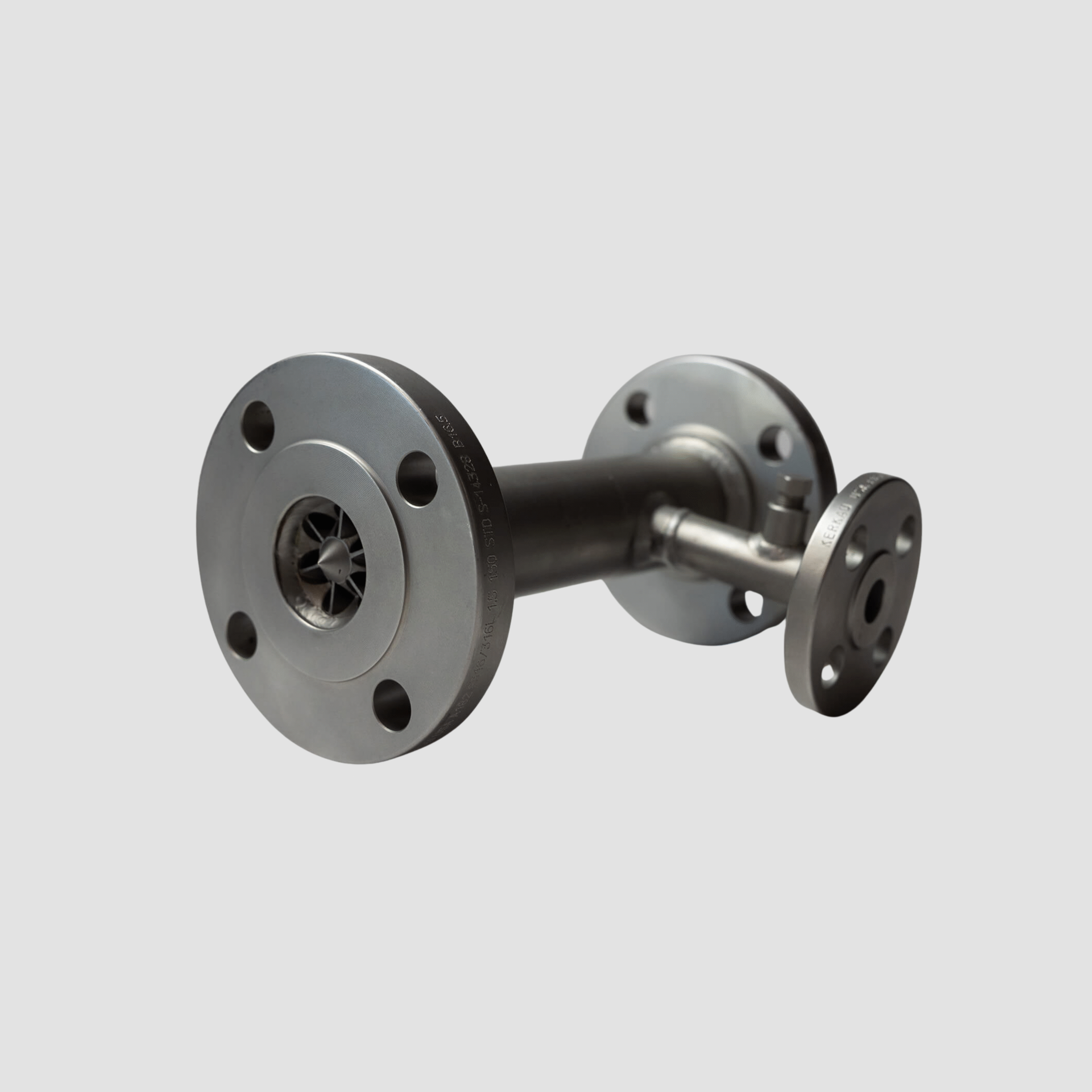

The Komax Direct Injection Steam Heater provides instantaneous and uniform heating by injecting steam directly into the process fluid. Its proprietary Equalizer™ mixing elements ensure complete condensation of steam without hammering, making it ideal for high-volume heating in industrial and municipal systems.

Direct steam-to-liquid contact

No scaling or fouling

High-efficiency heat transfer

Carbon steel or stainless steel

Up to 160°F (71°C)

ASME and ANSI compliant

Up to 200 psi

2" to 20" pipe diameter

Flanged or custom

Municipal sludge heating

Industrial process water heating

Food and beverage water systems

Pulp and paper mill systems

Tank filling lines

Water and wastewater

Sludge and slurry

Non-corrosive industrial fluids

Rapid temperature increase

No moving parts—low maintenance

Reduces energy and space requirements

Flow control valves

Temperature monitoring systems

Skid-mounted or inline configurations

Steam traps and condensate drains

From forging and casting to machining, assembly, and testing — every step is managed under one roof to ensure consistent quality, faster lead times, and zero compromise.

Get in touch with our team for additional information on product pricing, technical data, project support and more.