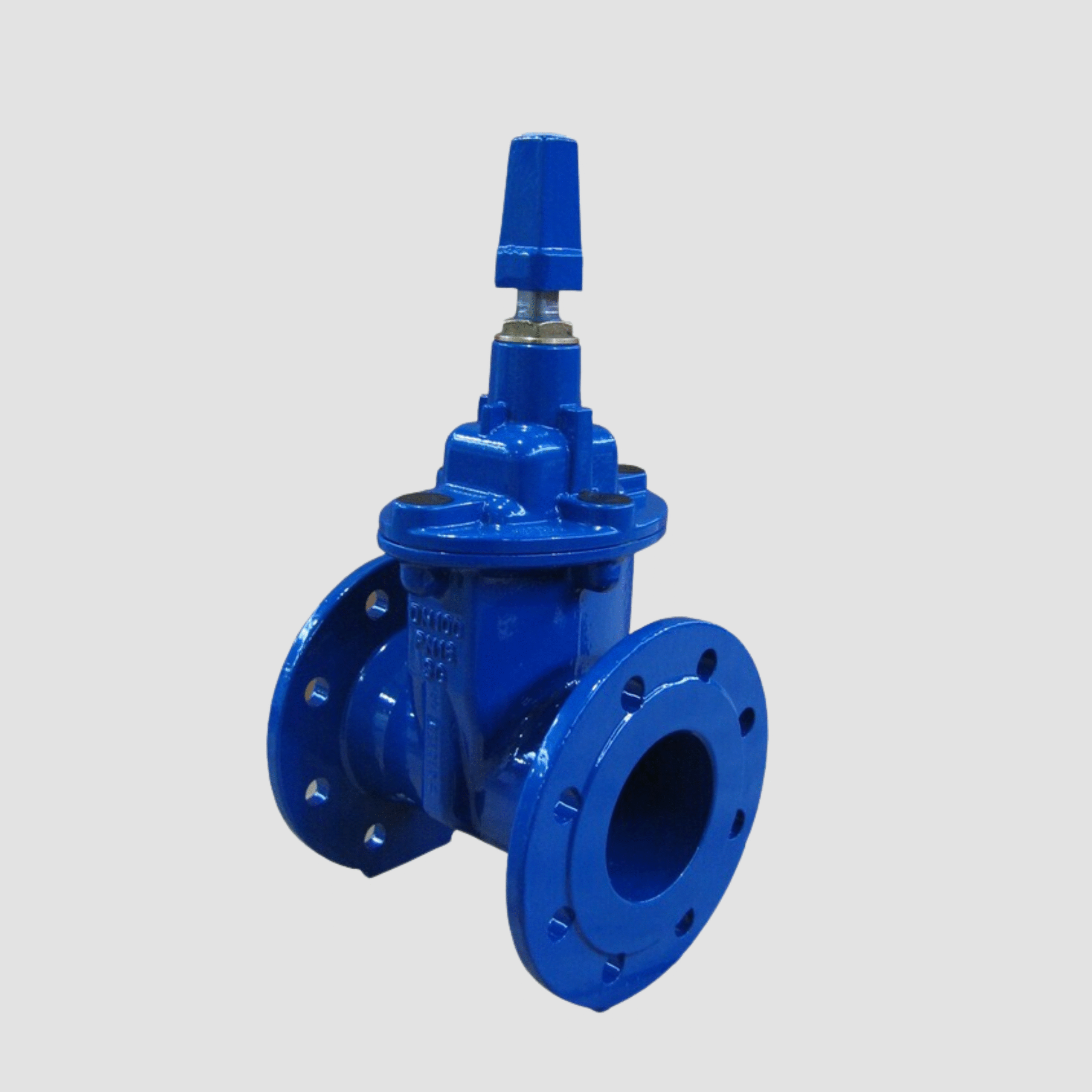

The EKO®plus is a reliable, resilient-seated gate valve designed for long-term performance in water, wastewater, gas, and desalination applications. Key design enhancements include sliding plastic caps on the wedge that minimize operating torque, a maintenance-free stem sealing system featuring triple O-rings, and corrosion-resistant materials suitable for critical pipeline installations. Its versatility is evident in its multiple configurations—including British Standard (BS 5163) types A & B, short and long face-to-face lengths, rising or non-rising stems, socket-to-socket connections, and actuator-ready versions.

DN 40–600 (BS/EN), wider range depending on configuration

PN 10/16/25 (BS/EN); ANSI Class 125/150 available

Short - EN 558 Basic Series 14; Long - Series 15 or R3 (BS 5163/ISO 5752)

Resilient-seated per BS 5163 & EN 1074

Ductile Iron EN‑GJS‑400‑15 (GGG‑40), epoxy-coated (GSK)

Stainless steel stem (1.4057); nut made of brass or bronze

Maintenance-free; corrosion-resistant

Type A & B (BS 5163); Socket-to-socket; Rising stem; Electric actuator; ANSI; SANS versions

EN 558 Basic Series 14 / 15, or BS R3

EPDM-coated over Ductile Iron

Triple O-ring; plastic sliding caps integrated during vulcanization

Up to 90% vacuum resistance

Ideal for:

Water treatment, distribution, and transmission systems

Desalination plants

Gas pipelines and pressure management applications

Pumping stations, retention basins, and dams

Suited for potable water, treated wastewater, desalinated water, and gas services—depending on wedge materials (EPDM for water, NBR for gas/wastewater).

Wide configuration flexibility: flange, socket, rising stem, automated actuation

Low torque operation minimizes actuator size and cost

High durability: proven design with long-term serviceability and burial readiness

Broad standard certifications: WRAS, DVGW, NSF (via coatings) available

Rising stem kits (for buried environments)

Electric actuators and advanced valves for electric operation

Socket connectors for VAG BAIO®plus system

ANSI and SANS variants for international standards

From forging and casting to machining, assembly, and testing — every step is managed under one roof to ensure consistent quality, faster lead times, and zero compromise.

Get in touch with our team for additional information on product pricing, technical data, project support and more.