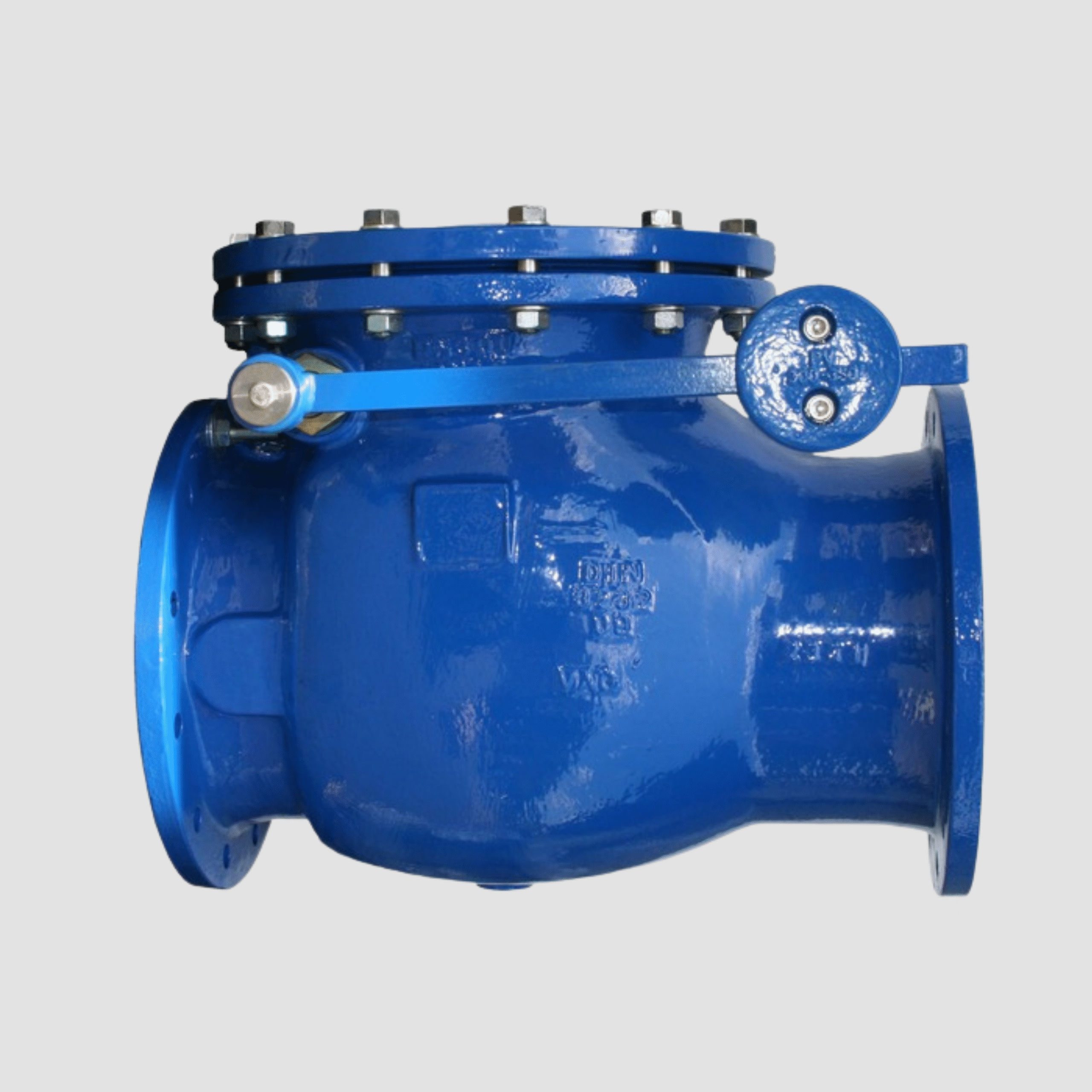

The VAG AW Disk Check Valve (Vertical Type) is a durable and robust non-return valve designed for vertical installation. Its metallic sealing ensures long-term operation without elastomer degradation, making it ideal for systems with fluctuating pressures. Equipped with a lever and weight, it ensures quick closure to prevent water hammer and reverse flow. The design supports vertical flow installations and is optimized for reliability in utility and industrial applications.

DN 50–DN 600

PN 10/16

According to EN 558 Series 48

Metallic sealing, vertical installation, with lever and weight

DN 50 to DN 600

EN 558 Series 48

EN-GJL-250 (GG25) / EN-GJS-400-15 (GGG40)

Stainless Steel

Drilled according to EN 1092-2

Metallic seat

PN 10/16

Vertical

EN-GJL-250 / EN-GJS-400-15

Epoxy resin coating, minimum thickness 250 µm

Waterworks and water treatment plants

Pumping stations and pipe systems

Power plants and process industries

Irrigation systems and utility water supply

Ideal for vertical pipelines requiring robust backflow prevention

Potable Water

Raw Water

Wastewater (with limited solid content)

Cooling Water

Firefighting Water Systems

Wide size availability from DN 50 to DN 600

Optional material and coating customizations

Long lifecycle with metallic sealing components

Supports integration into modern SCADA systems (on request)

Backed by Metaval’s quality assurance, testing, and project support

Counterweight adjustment options

Position indicator (mechanical or inductive)

Flushing connections for maintenance

Custom epoxy or polyamide coatings

Bypass arrangements for specific applications

From forging and casting to machining, assembly, and testing — every step is managed under one roof to ensure consistent quality, faster lead times, and zero compromise.

Get in touch with our team for additional information on product pricing, technical data, project support and more.