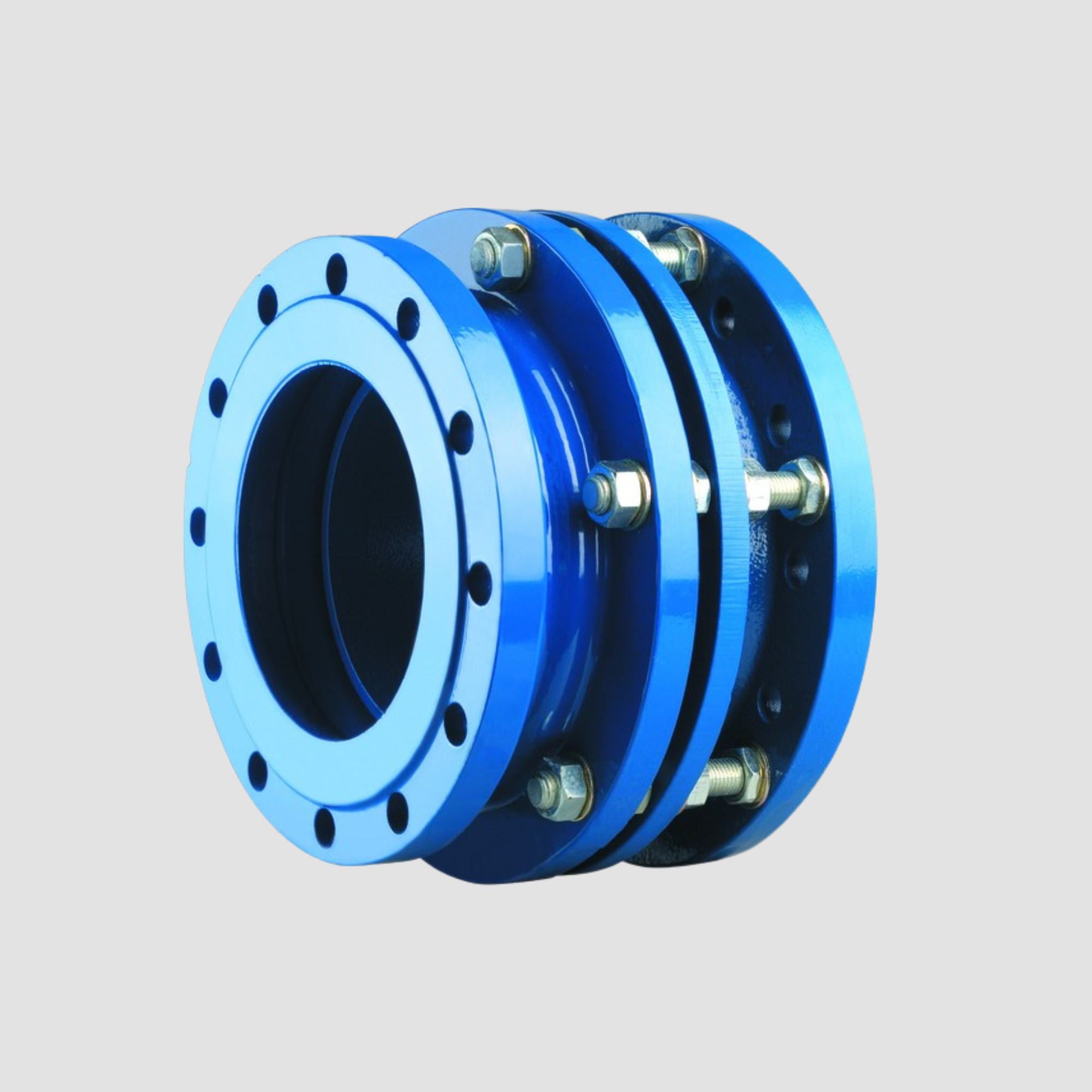

The VAG Dismantling Joint is a telescopic fitting designed to facilitate the simple installation and removal of valves, pumps, and pipe sections. Its adjustable length feature ensures precise adaptation to pipeline lengths, making it essential for maintenance and replacement tasks. Engineered for pressure pipelines in water and wastewater systems, it offers durability, ease of use, and secure sealing.

50 to DN 2000

PN 10 / 16 / 25

Adjustable installation length

DN 50 to DN 2000

Telescopic pipe with tie rods

Body: Ductile cast iron EN-GJS-400-15

Sealing: EPDM or NBR

Bolts/Nuts: Galvanized or stainless steel

Epoxy powder coating internally and externally (min. 250 µm)

Leak-proof as per EN 12266

Pressure Ratings: PN 10 / PN 16 / PN 25

Varies by DN (typically ±50mm to ±100mm)

Flanged (as per EN 1092-2)

As per EN 545 or customer specification

Up to 70°C (for water applications)

WRAS or DVGW (on request)

Water treatment plants

Pump stations

Municipal water networks

Wastewater and drainage pipelines

Industrial process water systems

Retrofit or valve replacement areas

Potable water

Raw water

Sewage

Industrial liquids (non-aggressive)

Enables easy installation/removal of components

Compensates axial movement and misalignment

Corrosion-resistant and pressure-stable

Reduces downtime during pipeline maintenance

Tie rods for thrust restraint

Custom face-to-face dimensions

Stainless steel bolts and nuts

Special coatings for aggressive environments

Lifting lugs for large-diameter units

From forging and casting to machining, assembly, and testing — every step is managed under one roof to ensure consistent quality, faster lead times, and zero compromise.

Get in touch with our team for additional information on product pricing, technical data, project support and more.