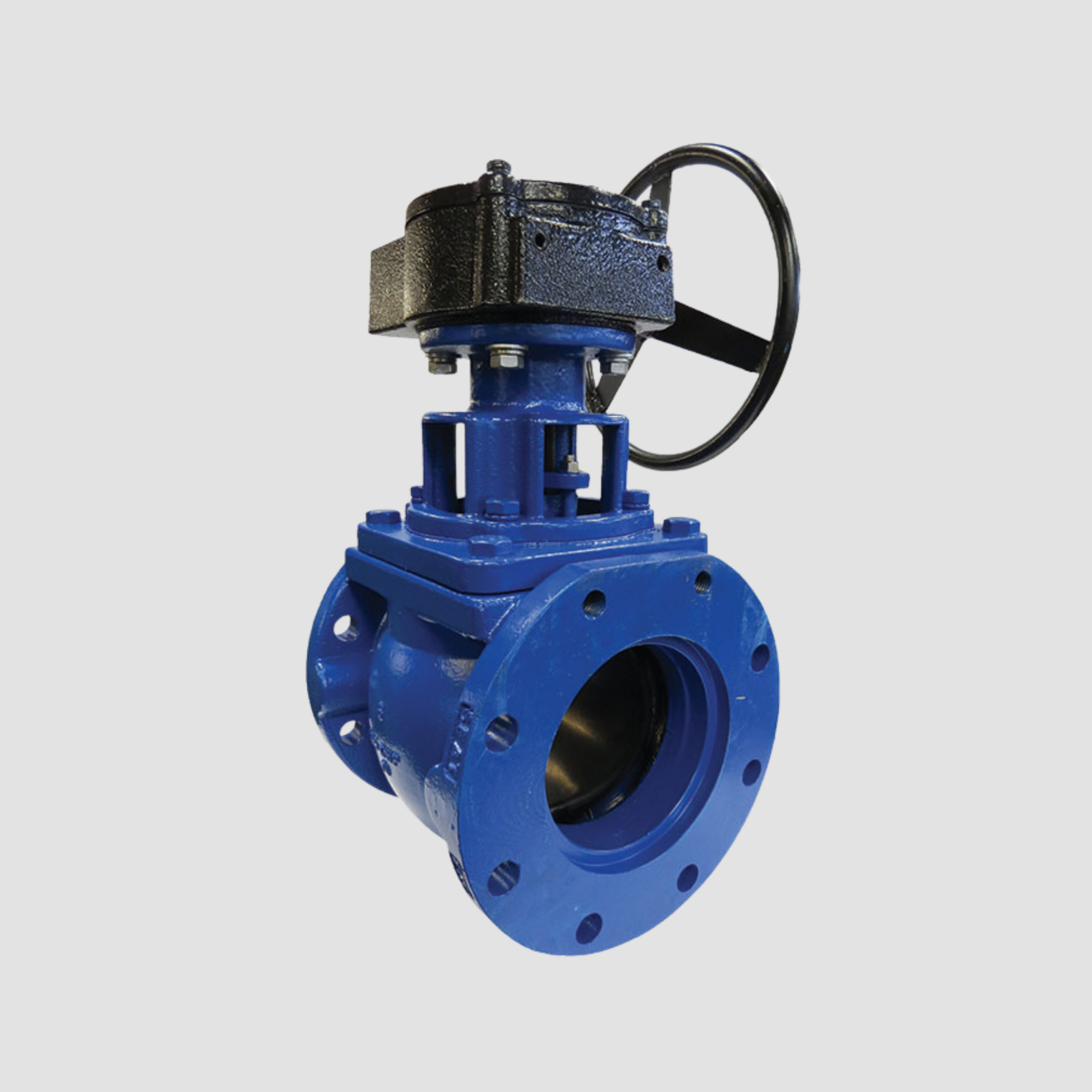

Rugged, field-proven eccentric plug valves with a flow-efficient round port design that ensures low head loss, excellent solids handling, and drop-tight bi-directional sealing.

Available in:

Figure B517 ECO‑Centric® – Flanged or mechanical joint, 3″–24″

Figure 517‑T – NPT-connected, compact lever-operated version for ½″–2½″ pipelines

ECO‑Centric®: 3″–24″ Figure 517‑T: ½″–2½″

Class 125 (175 psi ≤12″, 150 psi 14″–24″)

Compact lever/wrench operation or standard lug/flanged EN/ANSI

Round port—up to 50% less head loss vs rectangular ports

Body & Cover: Ductile Iron (ASTM A536 Grade 65‑45‑12), epoxy coated internally & externally (NSF‑61 ≥6 mil)

Ductile Iron with Buna‑N rubber coating (vulcanized)

External: 316 SS; Buried: optional stainless or galvanized steel

Rubber-coated plug provides bi-directional zero-leakage shut-off at full rated pressure

Weld-overlaid 95% nickel (ECO-Centric®)

Stainless steel 316 self-lubricating shaft bearings; grit excluders; adjustable, replaceable shaft packing

Ideal for water, wastewater, and industrial pipelines requiring reliable shut-off under harsh conditions. Used in water distribution, pump stations, treatment plants, and exposed or buried installations.

Designed for water and wastewater systems. Round port design ensures debris handling and minimizes clogging. Rubber plug seats (Buna-N) compatible with potable or reclaimed water—confirm material compliance for specialty fluids.

– Exceptional solids handling with minimal pressure loss

– Robust construction for long-term field durability

– Tight shut-off with low maintenance

– Options include wrench, lever, or gear operation

– Suitable for buried, exposed, or remote installations

– Chain lever or handwheel actuators (ECO‑Centric®)

– Vacuum service configurations (option VS), chainwheel (CW)

– NSF-61 compliant coatings and components for water certification

From forging and casting to machining, assembly, and testing — every step is managed under one roof to ensure consistent quality, faster lead times, and zero compromise.

Get in touch with our team for additional information on product pricing, technical data, project support and more.