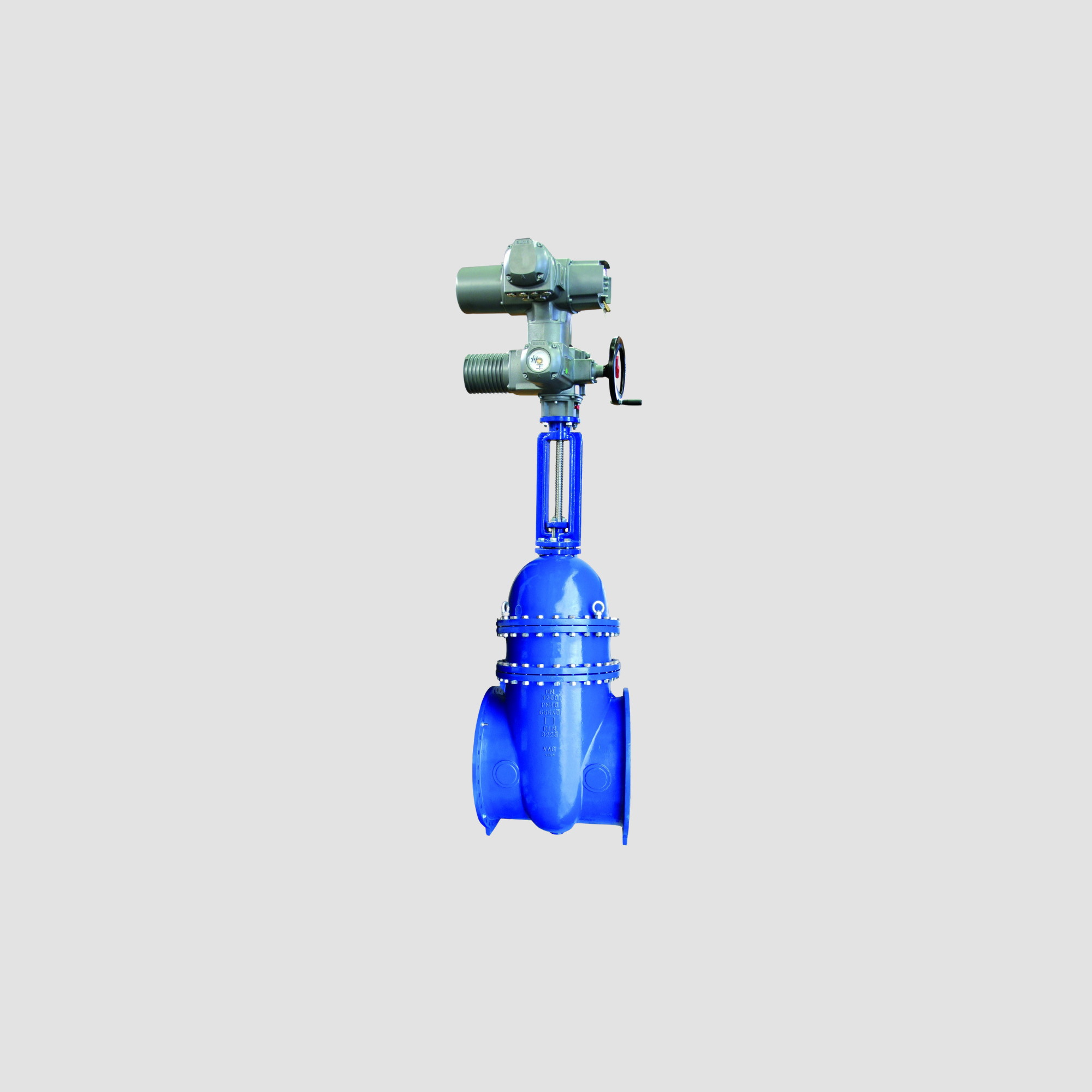

The VAG KFS Gate Valve is a durable, metallic-sealed valve engineered for highly demanding wastewater and industrial environments. Renowned for its minimal-maintenance design, the valve features zinc-free bronze seat rings and stem nuts for longevity. Available in multiple configurations tailored to diverse installation needs—such as rising or non-rising stems, manual or electric operation, and gearbox options for large diameters.

Rising Stem: DN 50–1200 Non-Rising Stem: DN 300–1200

Standard PN 10/16 suitable for heavy-duty applications

Short Flat-Type length per EN 558 Basic Series 14 (DIN‑3202 F4)

Metallic sealing per EN 1171 (DIN 3352‑2/3)

Ductile Iron EN‑GJS‑400‑15 (GGG‑40), epoxy coated inside/outside

Zinc-free bronze—excellent resistance to wastewater corrosion

Adjustable stuffing box, drain plug, electric actuator or gearbox options for DN 400/700/1200

EN 558 Basic Series 14 (flat type)

Rising stem (outside thread); Non‑rising stem (inside thread)

Stainless Steel 1.4057

Withstands up to 90% vacuum

• Municipal wastewater systems

• Industrial effluent and sewage pipelines

• Pressure and flow isolation systems in harsh environments

• Buried or elevated installations depending on stem choice

Designed to handle raw water, cooling water, municipal wastewater, weak acids, alkaline media, and oil-contaminated flows.

• Rising Stem – Handwheel

• Rising Stem – Electric Actuator

• Non-Rising Stem – Handwheel

• Non-Rising Stem – Electric Actuator

Robust, maintenance-minimal design for polluted or abrasive media

• Rising stem offers visual position indication; non-rising is compact for confined spaces

• Low internal friction with long-term sealing integrity

• Compatible with manual or automated control systems

• High vacuum resistance and custom options (e.g., burial kits, actuators, gearboxes)

• Gearbox or electric actuator (especially for DN 400, 700, 1200)

• Drain plug and stuffing box design for easy maintenance

• Stem extension or lantern enclosure kits for buried installations

• Specialized coatings or seal upgrades for corrosive environments

From forging and casting to machining, assembly, and testing — every step is managed under one roof to ensure consistent quality, faster lead times, and zero compromise.

Get in touch with our team for additional information on product pricing, technical data, project support and more.