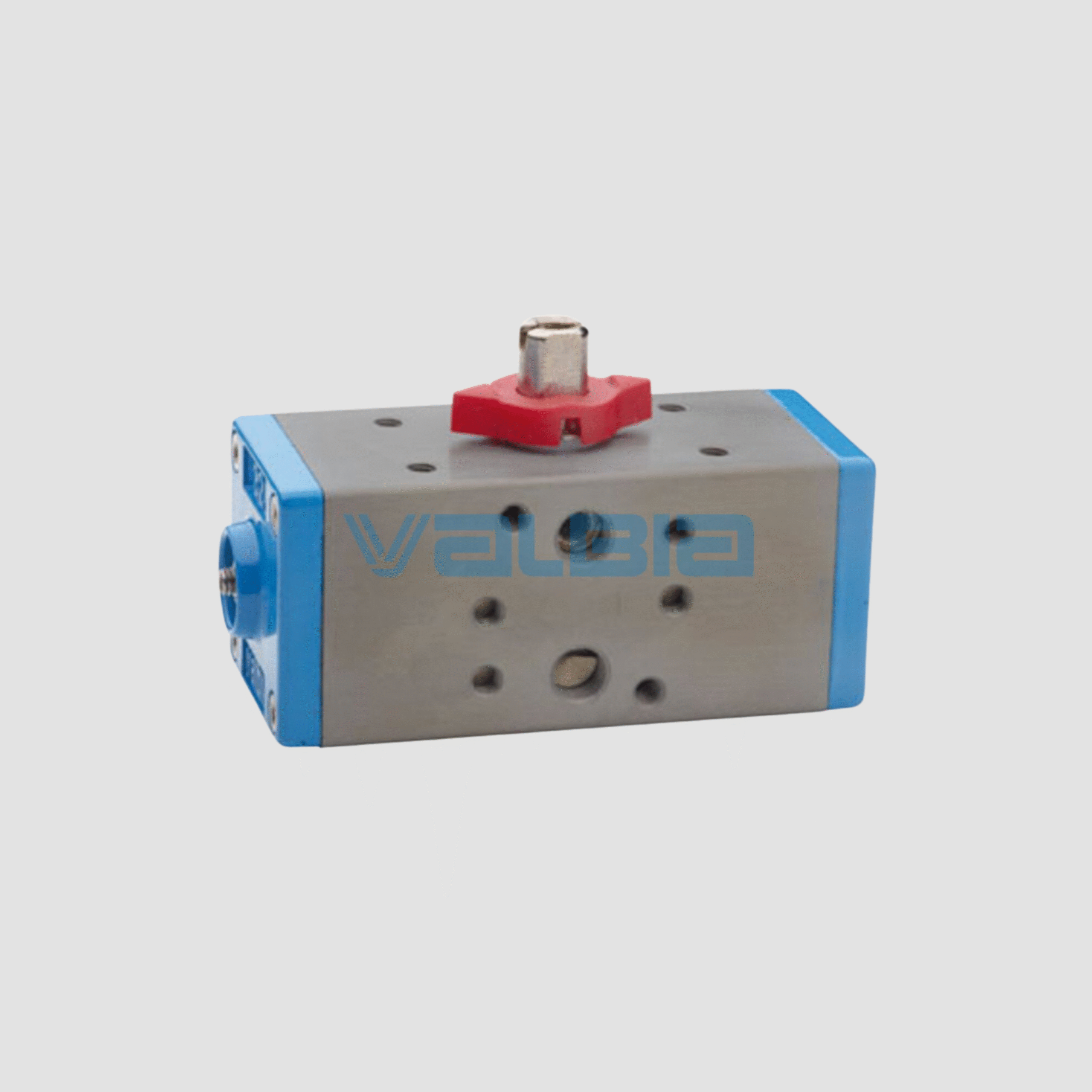

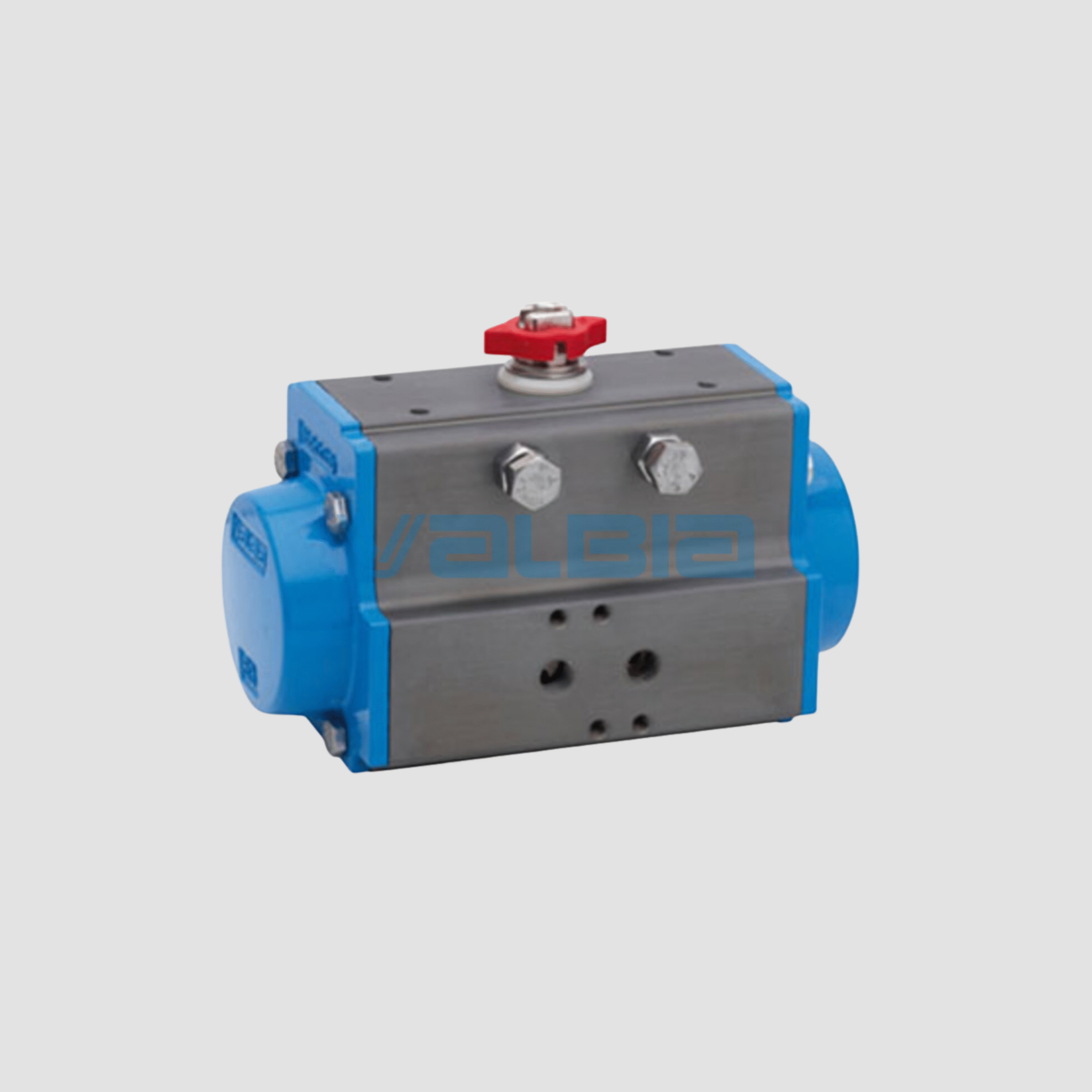

Valbia pneumatic actuators are high-performance, rack-and-pinion quarter-turn actuators engineered for industrial automation of ball, butterfly, and plug valves. Built with compact, corrosion-resistant construction, they offer reliable actuation with a variety of rotational and operating modes, backed by a patented design that enhances longevity and reduces leak paths.

Choice of 0–90° or 0–180° rotation via three series

Robust alloy construction with anti-blowout rack design

Custom coatings and seals for extreme environments

Twin rack-and-pinion for balanced torque and compact form

Standard FKM (Viton); optional silicone or low-temp variations

Output shaft: ISO 5211

Solenoid interface: Namur pattern

ATEX Zone 1/2 certification for explosive environments; PED/CE compliance

Series 82/83: Extruded hard-anodized aluminum bodies with nickel-plated steel pinions

Series 84: Stainless steel bodies for enhanced corrosion resistance

±5° via stainless steel cams and bolts

Max Pressure: ~8 bar (116 psi)

Operating Temp Range: –40 °C to +150 °C (depending on seals and coatings)

Industrial process actuation in chemical, food, and water sectors

Automation of valves in corrosive, high-temp, or cryogenic environments

High-cycle and safety-critical operations using modulating or failsafe versions

Marine and offshore valve automation requiring rugged design

Highly durable, low-maintenance rack-and-pinion mechanism

Precision control with tight end-position adjustment

Uniform torque output for consistent valve operation

Multiple material and finish combinations to match process conditions

Safe differential mounting/interface for accessories like limit switches or solenoids

Spring-Return (SR) Versions: Fail-safe function for valve positioning under pressure loss

Double-Acting (DA) Versions: Controlled open and close via air pressure in both directions

Special Finishes: Nickel plating or PTFE coatings for maximal corrosion resistance

High/Low Temp Options: Silicone, Viton, or NBR seals to suit extreme thermal environments

Accessories: Solenoid valve mounts, limit switches, manual overrides, and positioners

From forging and casting to machining, assembly, and testing — every step is managed under one roof to ensure consistent quality, faster lead times, and zero compromise.

Get in touch with our team for additional information on product pricing, technical data, project support and more.