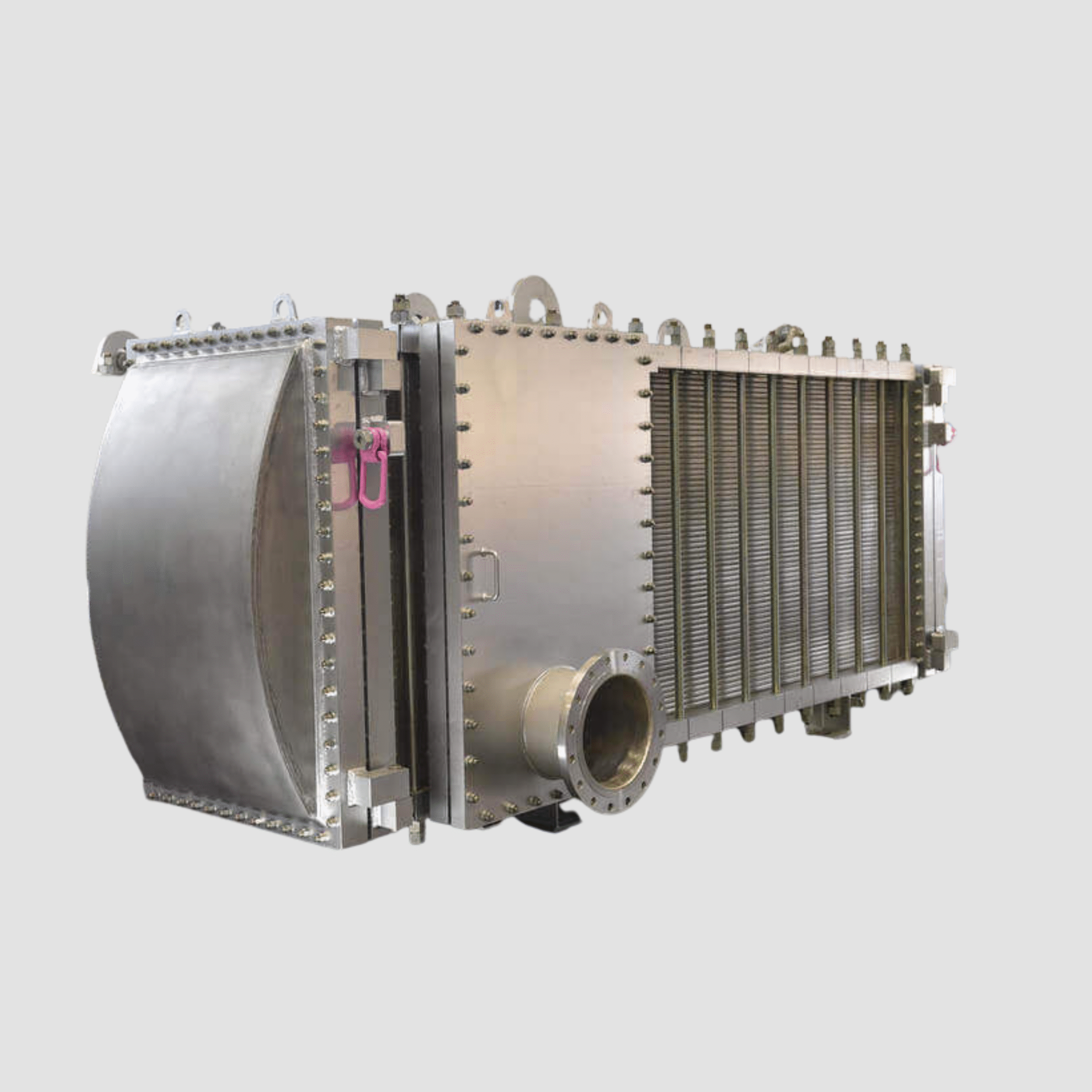

The Platular® Smart Hybrid is a high-performance, fully welded plate heat exchanger designed to handle dirty, viscous, and complex fluids in challenging industrial applications. Its unique multi-pass, counterflow design and openable construction make it an ideal solution for industries requiring maximum thermal efficiency, minimal fouling, and easy maintenance.

Fully welded, patented plate construction

Easy mechanical cleaning with openable design

Low pressure drop with high thermal transfer

Fully welded plate, counterflow, multi-pass

Dirty, viscous, and fouling-prone fluids

Liquid-liquid, condensation, evaporation, gas-gas, and more

Five custom stream geometries for optimal hydraulic/thermal performance

Openable “visitable” construction with no internal flat gaskets

Allows mechanical cleaning without disassembly

Engineered for low ΔP with turbulent flow paths

Chemical and petrochemical industries

Fine chemical and pharmaceutical production

Food and beverage processing

District heating and HVAC

Gas-to-gas heat recovery

Mining and pulp & paper operations

Energy recovery systems

Sludges, slurries, and heavily contaminated fluids

Steam, VOC vapors, and condensates

Clean gas, air, or water in high-efficiency applications

Handles extreme fouling and cleaning cycles

Delivers high thermal efficiency with compact footprint

Designed for long-duration, low-maintenance operations

Suitable for high-viscosity or particulate-laden streams

Type X: Optimized for dirty fluids with minimal fouling

Type IJS: Compact design used since the 1960s

Type PCV: High-pressure version for district heating applications

Immersed Designs: For use inside distillation columns or tanks

From forging and casting to machining, assembly, and testing — every step is managed under one roof to ensure consistent quality, faster lead times, and zero compromise.

Get in touch with our team for additional information on product pricing, technical data, project support and more.