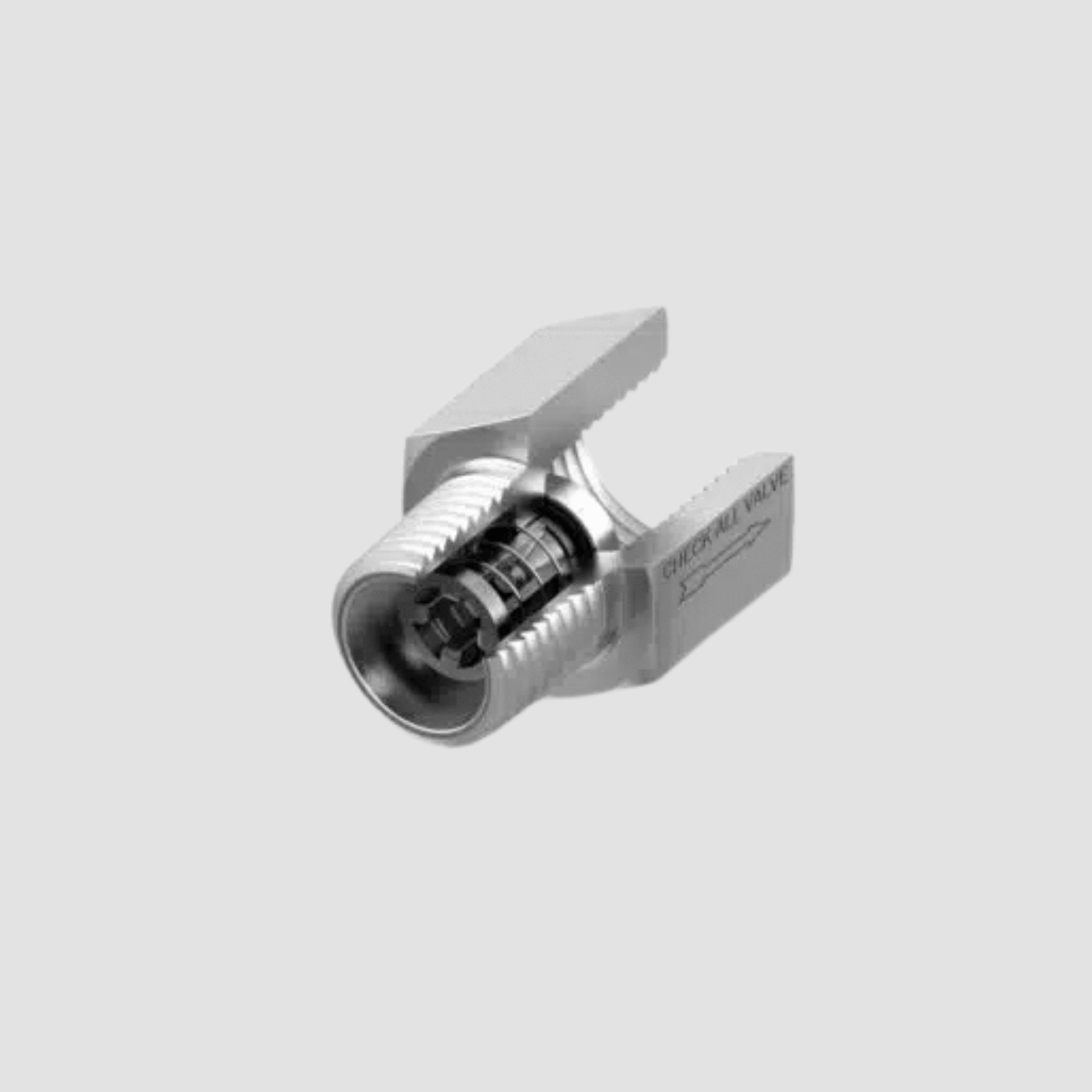

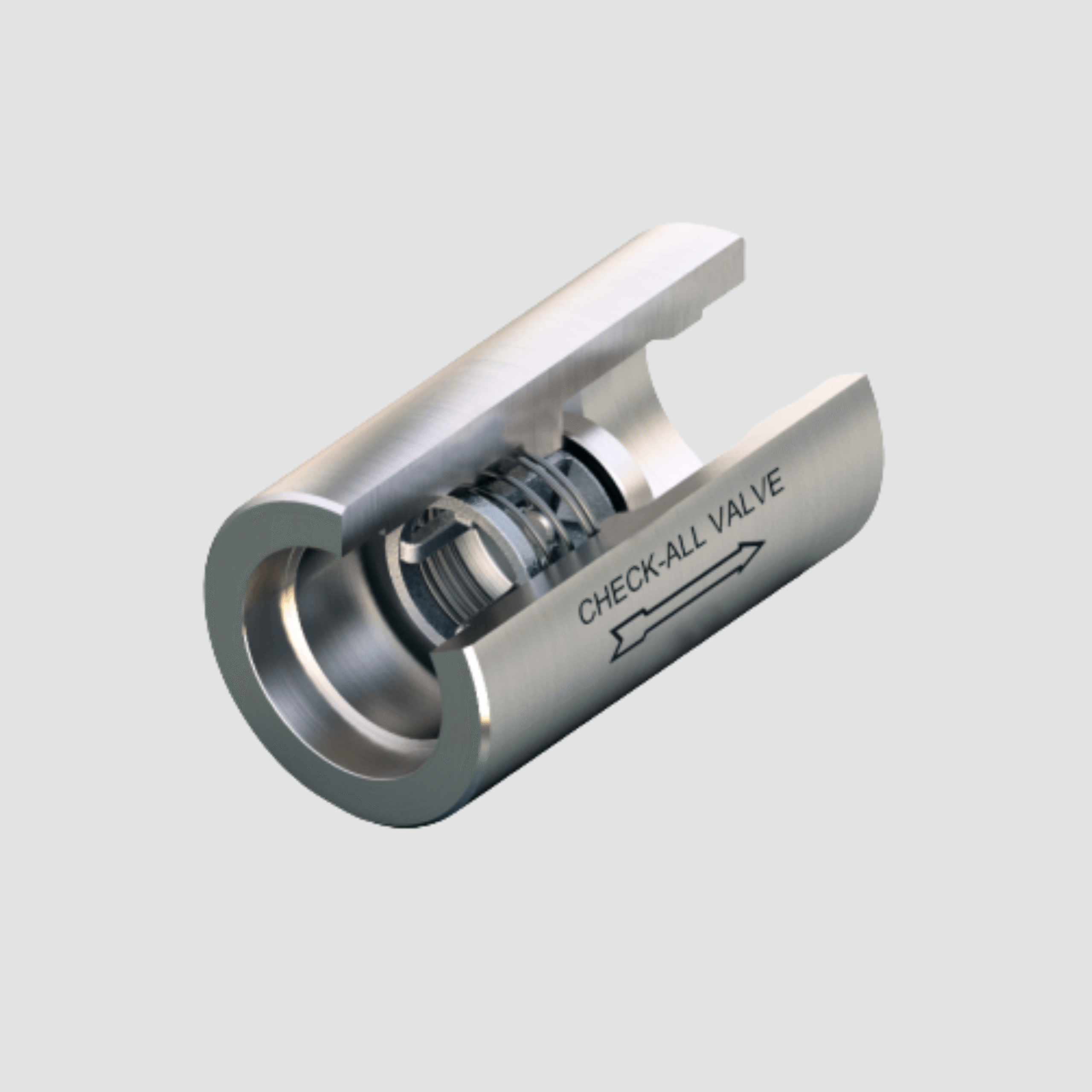

The Check-All silent check valves are a comprehensive lineup of spring-assisted, poppet-style check valves engineered to minimize water hammer and operate silently. They are designed for rapid closing via short-stroke action and offer smooth sealing through turbulence-assisted seat engagement—ideal for systems requiring precise, quiet backflow prevention.

Wide variety of connection styles

Smooth, silent operation

Flexible spring-cracking settings

In-line spring-loaded poppet mechanism

Wide spring-setting flexibility from low (vacuum applications) to high (up to 10,000 psi systems)

From 1/8" NPT up to 20" flange connections

Soft (PTFE / elastomer) or metal-to-metal

Multiple alloys available—including stainless steel, titanium, Alloy 20, C-276, Monel 400, and more

Backflow protection across liquids and gases

Support for clean process systems with stringent leak requirements

Meter protection and pump isolation in water networks

Applications requiring silent operation—particularly in tight or noise-sensitive environments

Check-All offers a diverse collection of check valve styles to suit nearly any industrial need:

Adapter (AM, AF)

Bushing (BU, BR)

Butt Weld (B4, B8)

Connector (CN, CR)

Flange Insert (F1, F6, FP)

Horizontal / Vertical Flanged & Drilled (HV, HT)

Insert series (U1, R1, U3, UR, LP)

Mini Check (M1, M8)

Sanitary Cartridge (SC)

Sanitary Insert (3S, CB, TC)

Straight-Sided Insert (SI)

Tubing Check (TV, TF)

Union Insert (UV)

Vacuum Flange Insert (VI)

Wafer Insert (WV)

Custom Spring Check Design (CAV)

Customizable spring settings for precise cracking and reseal behaviors

Multiple installation options: horizontal or vertical, with no performance change

Excellent performance in both pressure relief and vacuum breaker roles

Built for longevity with minimal maintenance in harsh or high-cycle environments

Special spring materials (stainless steel, titanium, Inconel, etc.)

PTFE-encapsulated springs for corrosive service

Custom connection styles or configurations via CAV series

Documentation packages—data sheets, sizing charts, technical support options

From forging and casting to machining, assembly, and testing — every step is managed under one roof to ensure consistent quality, faster lead times, and zero compromise.

Get in touch with our team for additional information on product pricing, technical data, project support and more.