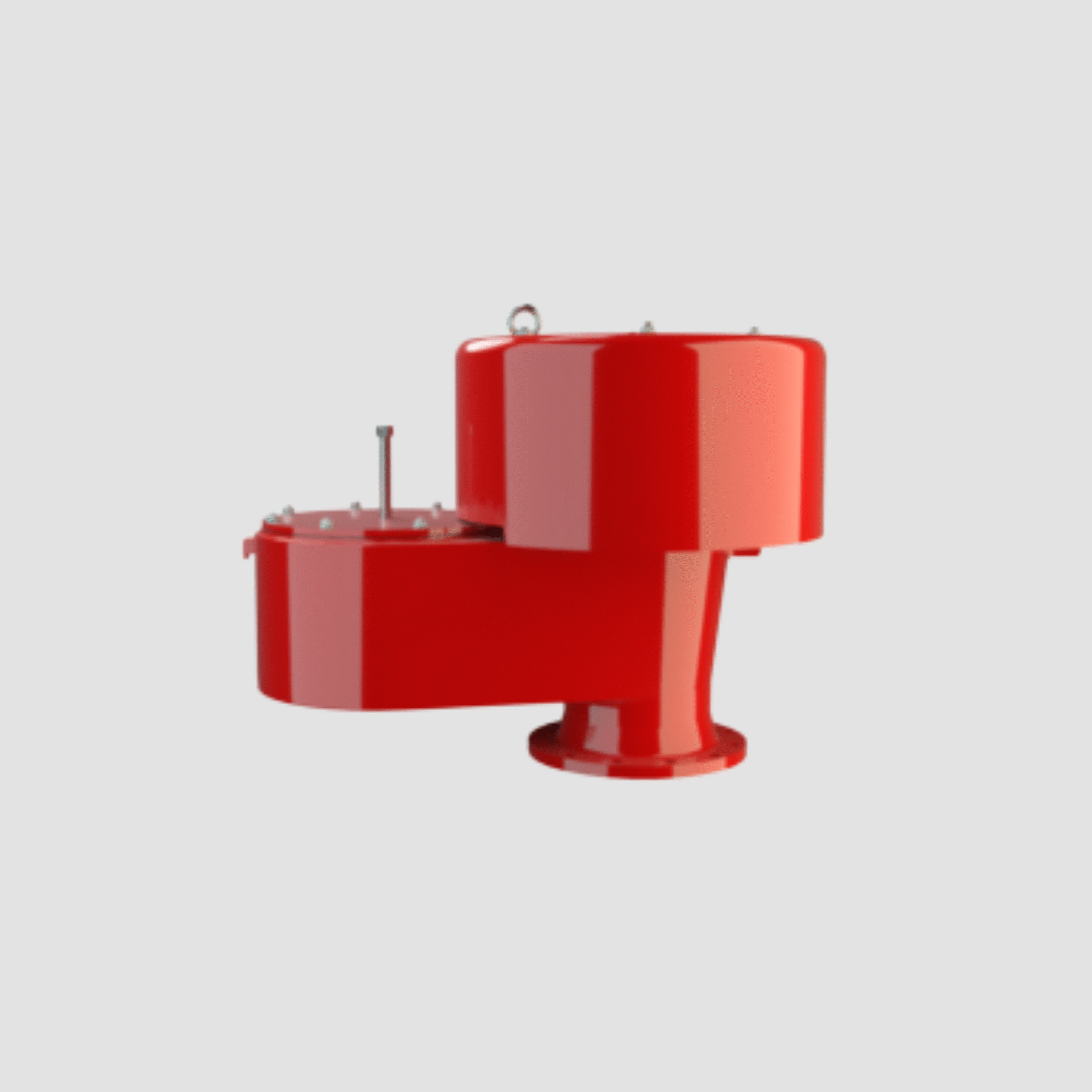

The PROTEGO® VD/SV is a highly engineered pressure and vacuum relief valve that ensures optimum protection of storage tanks and process vessels from excessive overpressure or vacuum. Designed with “full lift type” technology, it ensures extremely tight sealing up to the set pressure and vacuum, reducing emissions and product loss. The valve opens with just 10% overpressure, offering a high flow capacity while maintaining stable pallet operation. Its stainless steel construction, corrosion-resistant seals, and optimized flow dynamics make it ideal for demanding environments.

40–300

+2.0 to +60 mbar

–2.0 to –60 mbar

DN 40 to DN 300

+2.0 to +60 mbar (0.8 to 24 in. W.C.)

Suitable for use in hazardous zones

EN 1092-1, Form B1 ASME B16.5 Class 150 R.F.

–2.0 to –60 mbar (0.8 to 24 in. W.C.)

10% technology; extremely low leakage

Up to +60 °C (higher on request)

Atmospheric and low-pressure storage tanks

Chemical and petrochemical processing

Tank farms and distribution terminals

Vessels requiring minimal product loss and high flow relief

Facilities with environmental emission compliance standards

Hydrocarbons

Solvents

Alcohols

Inert gases

Air/vapor mixtures in hazardous environments

Full lift opening with 10% overpressure

Superior sealing for minimal vapor loss

Resistant to sticky and corrosive media

Stable pallet operation under varying flow conditions

Optional heating jacket available for low-temp media

Heating Jacket Version: VD/SV-H

Valve Pallet Options:

Aluminum or stainless steel

FEP, PTFE, metal-to-metal sealing

Custom Pressure/Vacuum Settings

Special Coatings: ECTFE for aggressive media

Condensate Drain Feature

Weather Hoods: Stainless steel, corrosion-resistant

Spring-Loaded Design for Higher Pressures (on request)

From forging and casting to machining, assembly, and testing — every step is managed under one roof to ensure consistent quality, faster lead times, and zero compromise.

Get in touch with our team for additional information on product pricing, technical data, project support and more.