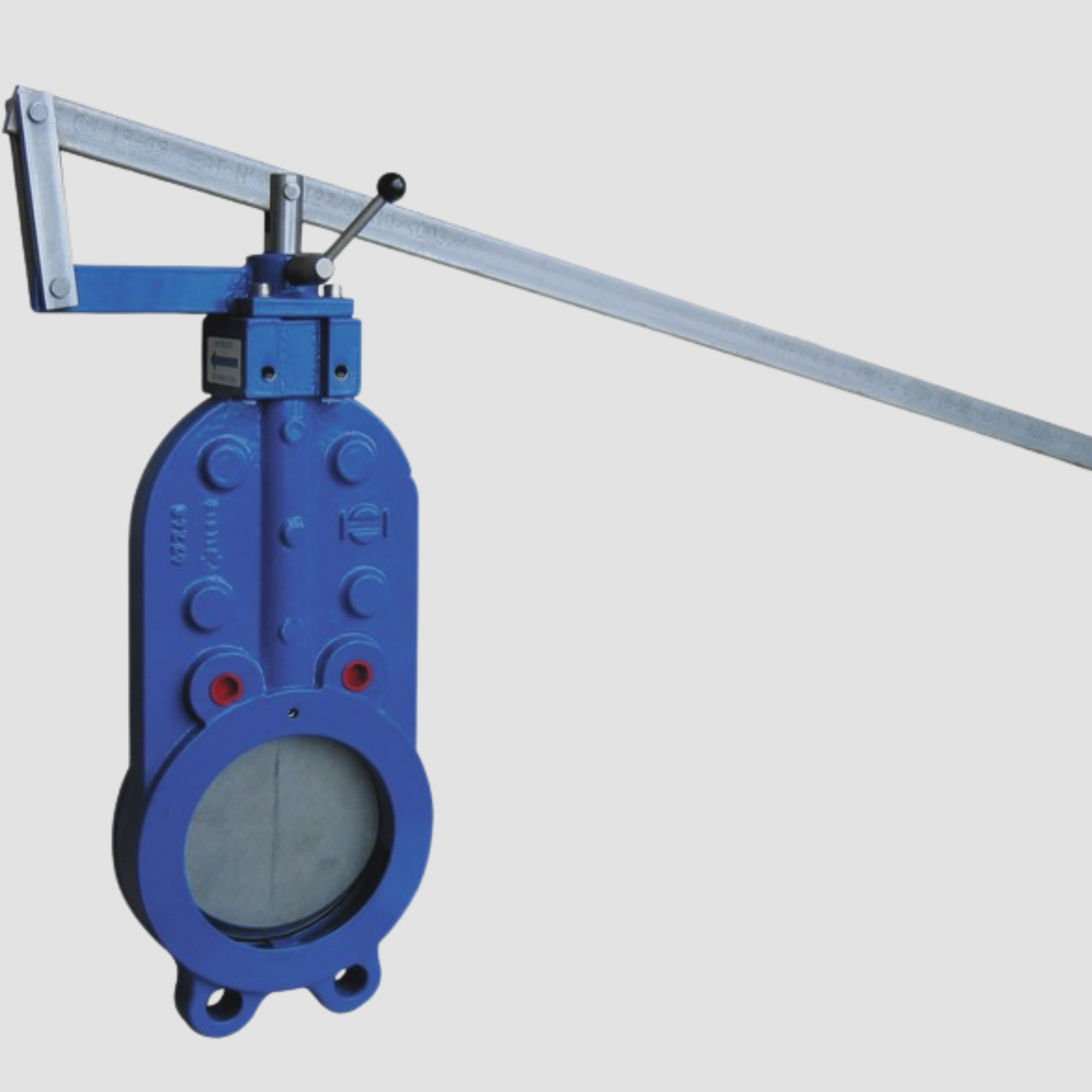

Compact, fully‑flanged knife gate valve with a solid monoblock body. Features a fully chambered knife and a maintenance‑free shaft seal with built-in scrapers to prolong lifespan and prevent clogging—ideal for wastewater and industrial pipelines.

DN 50 – 300

PN 10

EN 558 Basic Series 20 (DIN 3202 K1)

Fully enclosed to prevent contamination ingress

Eliminates friction from side seals, ensuring smooth oper

Includes drain plug (G ¼″) for maintenance

Equipped with G ¼″ connection to avoid pipeline clogging

Efficient operation without requiring a gearbox

Preferred upright orientation (10 to 2 o’clock) with flow direction

Hand Lever Version – operated via lever with default internal shaft

Optional External Shaft – configurable with lever and weight (on request)

Body: Ductile Iron EN‑GJS‑400‑15 (GGG‑40)

Knife & Internals: Knife: Stainless Steel 1.4301; Shaft components: Stainless Steel A2; O-Ring: NBR; Counter-flange: Steel S235 JRG2

Coating: Epoxy applied internally and externally for corrosion protection

Wastewater treatment networks

Industrial and dam-related water systems

High-contamination lines where robust sealing is crucial

Suitable for wastewater, raw water, and water with solids content; resistant to contamination from suspended solids

Cavitation-free regulation

Compact installation in valve chambers

Manual and electric actuation flexibility

Long service life due to wear-resistant seat

Minimal operating torque through balanced pressure compensation

Weight-assisted lever for manual operation

Protective guards or actuator mounting bases (available upon request)

From forging and casting to machining, assembly, and testing — every step is managed under one roof to ensure consistent quality, faster lead times, and zero compromise.

Get in touch with our team for additional information on product pricing, technical data, project support and more.