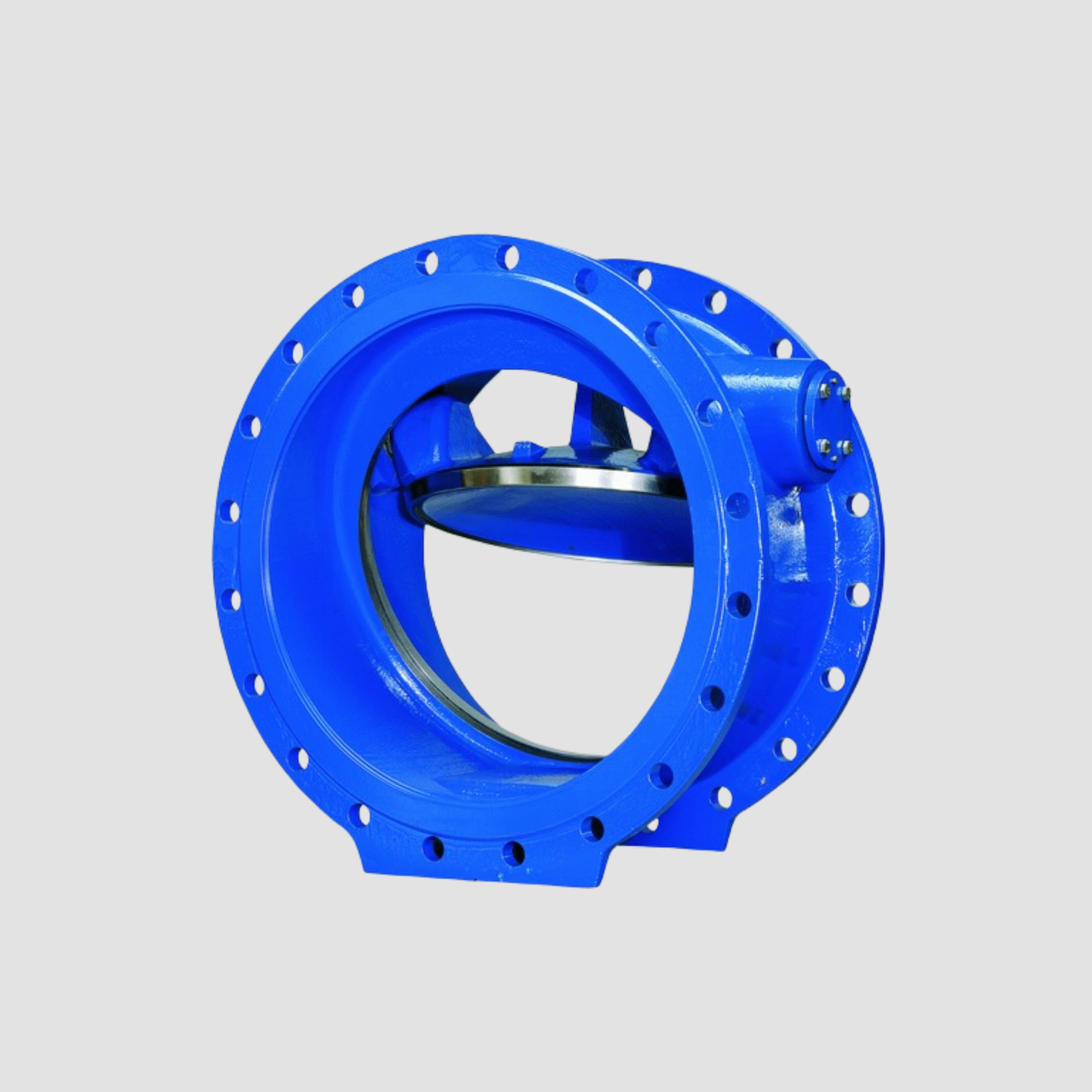

A metallic-sealing, full-flange check valve engineered for minimized closing time and energy-efficient flow. Its slanted, aircraft-inspired tilting disk opens fully even at low flow and closes just before reversal to avoid water hammer. Available with an optional internal damping unit to heat-shield against pressure surges.

DN 200–1400

PN 10 / PN 16 / PN 25

EN 558, Basic Series 14 (DIN 3202 F4)

EN 16767 compliant; maintenance-free

Opens smoothly even at low velocities (“wing effect”)—high energy efficiency and minimal noise/turbulence

Reduces pressure surges—activates ~10–15% before full close

Slanted seat shortens disk stroke by ~30%, enabling shorter closing time and reduced backflow

No external moving parts; all components enclosed for minimal space use and safety

Ideal for water treatment, distribution systems, pretreated sewage, power plants, and industrial pipelines—especially where valve performance under pressure reversal and minimizing water hammer matter.

Standard SKR (no damping) – default, high-efficiency model.

– Body & Disk: Ductile Iron EN‑GJS‑400‑15 (GGG‑40)

– Sealing Surface: Microfinished high‑alloy weld overlay—premium corrosion and wear

Epoxy coating, inside and out, adheres to GSK standards for durable corrosion protection.

Designed for water, wastewater, and seawater. The epoxy and weld overlay sealing ensure reliable performance in aggressive or contaminated me

– Fast Closing: Slanted, reduced-stroke disk enables aggressive closing before reversal

– Energy Efficient: “Wing effect” keeps disk open smoothly at low flow, reducing headloss

– Low Maintenance: Robust, minimal-wear design with no external micro-exposed mechanisms

– Pressure Surge Protection: Internal damper option gives an extra buffer against harmful pressure spikes

– Space-Efficient Design: Compact, streamlined structure ideal for tight installations

– Internal Damping Unit (factory-fit or retrofittable)

– Fully Rubber-Lined Version suitable for seawater applications

From forging and casting to machining, assembly, and testing — every step is managed under one roof to ensure consistent quality, faster lead times, and zero compromise.

Get in touch with our team for additional information on product pricing, technical data, project support and more.